产品价格2300.00元/件

最小起订量:1 件可售数量:10000 件

电动滚筒简介:

根据带式输送机的某些特殊场合需要,又出现了介于分离式驱动和电动滚筒驱动形式之间的减速装置在滚筒体内部、电动机在滚筒体外面的外装式电动滚筒。

与分离式驱动装置相比,电动滚筒具有结构紧凑、传动效率高、噪声低、使用寿命长,运转平稳、工作可靠、密封性好、占据空间小、安装方便等诸多优点,并且适合在各种恶劣环境条件下工作。包括潮湿、泥泞、粉尘多的工作环境。

电动滚筒工作条件:

1、使用环境温度为一15℃、+40℃;

2、海拔高度不超过1000米;

3、输送物料的温度不超过60℃;

4、电压380V,频率50Hz。

电动滚筒范围特点:

电动滚筒作为皮带运输机和提升等设备的动力,广泛应用于矿山、冶金、化工、煤炭、建材、电力、粮食及交通运输等部门。

1、可以代替广泛使用着的电机一减速器型式的外驱动装置,用来构成胶带输送机,可输送煤炭、矿石、砂子、水泥、面粉等散装物料, 也可以输送麻包、设备等成件物品。

2、 结构简单紧凑,占用空间面积小。

3、 密封良好,适用于粉尘浓度大、潮湿泥泞的工作场所。

4、 使用维修方便,操作安全可靠,寿命长。

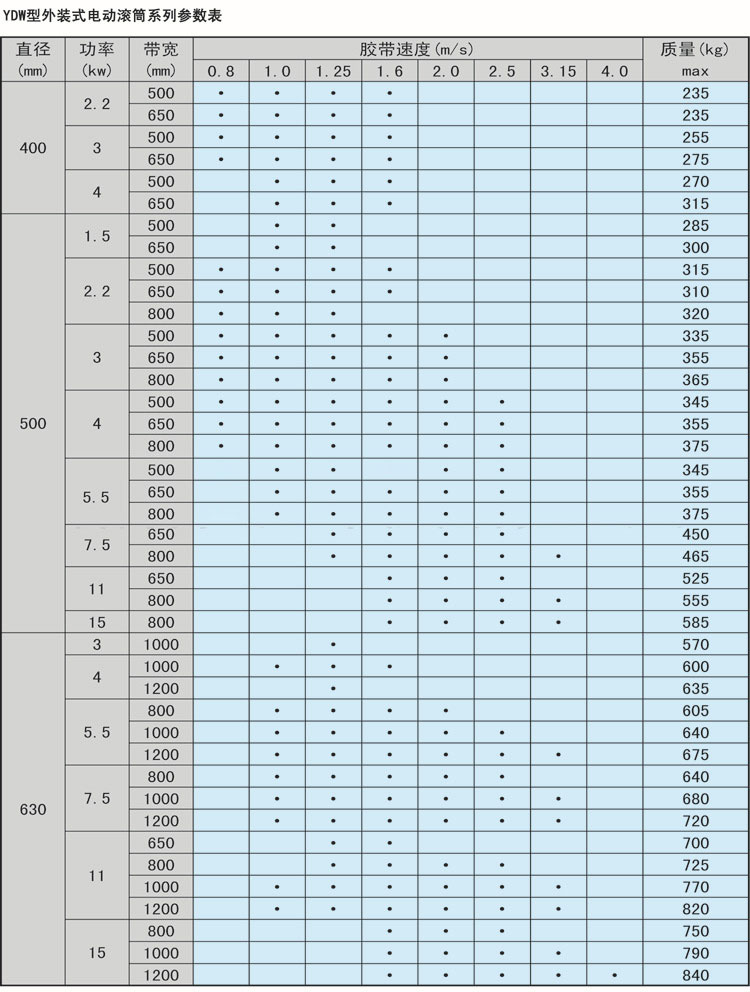

电动滚筒参数:

WD1外装式电动滚筒配用电机型号及系列参数表

|

筒径

D(mm)

|

带宽

B(mm)

|

电机

|

带速V(m/s)

|

|||||||||

|

功率kw

|

型号

|

0.8

|

1.0

|

1.25

|

1.6

|

2.0

|

2.5

|

3.15

|

4.0

|

5.0

|

||

|

400

|

400

500

650

|

2.2

|

112M-6

|

○

|

○

|

○

|

○

|

|

|

|

|

|

|

100L+-4

|

|

|

|

○

|

○

|

|

|

|

|

|||

|

3.0

|

132S-6

|

○

|

○

|

○

|

|

|

|

|

|

|

||

|

100L2-4

|

|

|

|

○

|

○

|

○

|

|

|

|

|||

|

500

650

800

|

4.0

|

132M1-6

|

|

○

|

○

|

○

|

|

|

|

|

|

|

|

112M-4

|

|

|

|

○

|

○

|

○

|

|

|

|

|||

|

5.5

|

132M2-6

|

○

|

○

|

○

|

○

|

|

|

|

|

|

||

|

132S-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

500

|

400

500

650

800

|

3.0

|

132S-6

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

|

100L2-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

4.0

|

132M1-6

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

||

|

112M-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

5.5

|

132M2-6

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

||

|

132S-4

|

|

|

|

|

○

|

|

|

|

|

|||

|

500

650

800

1000

|

7.5

|

160M-6

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

|

|

132M-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

11.0

|

160L-6

|

○

|

○

|

○

|

○

|

|

|

|

|

|

||

|

160M-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

15.0

|

180L-6

|

○

|

|

○

|

○

|

○

|

○

|

|

|

|

||

|

160L-4

|

|

|

|

|

○

|

○

|

|

|

|

|||

|

630

|

650

800

1000

|

4.0

|

132M1-6

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

5.5

|

132M2-6

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

||

|

650

800

1000

1200

|

7.5

|

160M-6

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

|

11.0

|

160L-6

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

||

|

15.0

|

180L-6

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

||

|

800

1000

1200

1400

|

18.5

|

200L1-6

|

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

|

22.0

|

200L2-6

|

|

|

○

|

○

|

○

|

○

|

○

|

|

|

||

|

30.0

|

200L-4

|

|

|

|

|

○

|

○

|

○

|

|

|

||

|

800

|

800

1000

1200

|

7.5

|

160M-6

|

|

|

|

○

|

○

|

○

|

○

|

|

|

|

11.0

|

160L-6

|

|

|

|

○

|

○

|

○

|

○

|

|

|

||

|

15.0

|

180L-6

|

|

|

|

○

|

○

|

○

|

○

|

|

|

||

|

800

1000

1200

1400

|

18.5

|

200L1-6

|

|

|

|

○

|

○

|

○

|

○

|

○

|

|

|

|

22.0

|

200L2-6

|

|

|

|

○

|

○

|

○

|

○

|

○

|

|

||

|

30.0

|

200L-4

|

|

|

|

|

|

○

|

○

|

○

|

|

||

WD2外装式电动滚筒配用电机型号及其系列参数表

|

筒径

D(mm)

|

带宽

B(mm)

|

电机

|

带速V(m/s)

|

|||||||

|

功率kw

|

型号

|

1.25

|

1.6

|

2.0

|

2.5

|

3.15

|

4.0

|

5.0

|

||

|

630

|

650

800

1000

1200

1400

|

30

|

225M-6

|

|

|

○

|

○

|

○

|

○

|

|

|

250M-8

|

|

○

|

○

|

○

|

○

|

|

|

|||

|

37

|

250M-6

|

|

|

○

|

○

|

○

|

○

|

|

||

|

280S-8

|

|

○

|

○

|

○

|

○

|

|

|

|||

|

800

1000

1200

1400

|

45

|

280S-6

|

|

|

○

|

○

|

○

|

○

|

|

|

|

280M-8

|

|

|

○

|

○

|

○

|

|

|

|||

|

800

|

800

1000

1200

1400

1600

|

37

|

250M-6

|

|

|

○

|

○

|

○

|

○

|

|

|

280S-8

|

|

○

|

○

|

○

|

○

|

|

|

|||

|

45

|

280S-6

|

|

|

○

|

○

|

○

|

○

|

|

||

|

280M-8

|

|

○

|

○

|

○

|

○

|

|

|

|||

|

1000

1200

1400

1600

|

55

|

280M-8

|

|

|

|

|

○

|

○

|

|

|

|

315S-8

|

|

|

|

○

|

○

|

|

|

|||

|

75

|

315S-6

|

|

|

|

|

○

|

○

|

|

||

|

315M1-8

|

|

|

|

○

|

○

|

|

|

|||

|

1000

|

800

1000

1200

1400

1600

|

45

|

280S-6

|

|

|

|

○

|

○

|

○

|

○

|

|

280M-8

|

|

|

○

|

○

|

○

|

|

|

|||

|

1000

1200

1400

1600

|

55

|

280M-6

|

|

|

|

○

|

○

|

○

|

|

|

|

315S-8

|

|

|

|

|

|

|

|

|||

|

75

|

315S-6

|

|

|

|

○

|

○

|

○

|

○

|

||

|

315M1-8

|

|

|

○

|

○

|

○

|

○

|

|

|||

|

90

|

315M1-6

|

|

|

|

○

|

○

|

○

|

○

|

||

|

315M2-8

|

|

|

○

|

○

|

○

|

○

|

○

|

|||

|

110

|

315M2-6

|

|

|

|

○

|

○

|

○

|

○

|

||

|

315M3-8

|

|

|

○

|

○

|

○

|

○

|

○

|

|||

|

1250

|

1200

1400

1600

|

75

|

315S-6

|

|

|

|

|

○

|

○

|

○

|

|

315M1-8

|

|

|

|

○

|

○

|

○

|

|

|||

|

90

|

315M1-6

|

|

|

|

|

○

|

○

|

○

|

||

|

315M2-8

|

|

|

|

○

|

○

|

○

|

|

|||

|

110

|

315M2-6

|

|

|

|

|

○

|

○

|

○

|

||

|

315M3-8

|

|

|

|

○

|

○

|

○

|

|

|||

|

132

|

315M3-6

|

|

|

|

|

○

|

○

|

○

|

||

|

400S2-8

|

|

|

|

○

|

○

|

○

|

|

|||

|

1400

|

1400

1600

2000

|

132

|

315M3-6

|

|

|

|

|

○

|

○

|

○

|

|

400S2-8

|

|

|

|

○

|

○

|

○

|

|

|||

|

160

|

355M3-6

|

|

|

|

|

○

|

○

|

○

|

||

|

400S3-8

|

|

|

|

|

○

|

○

|

|

|||

|

185

|

400S2-6

|

|

|

|

|

|

○

|

○

|

||

|

400M2-8

|

|

|

|

|

○

|

○

|

|

|||

|

220

|

400S3-6

|

|

|

|

|

|

○

|

○

|

||

|

400M3-8

|

|

|

|

|

○

|

○

|

||||